Sandwich Roof & Wall Panel Production Line

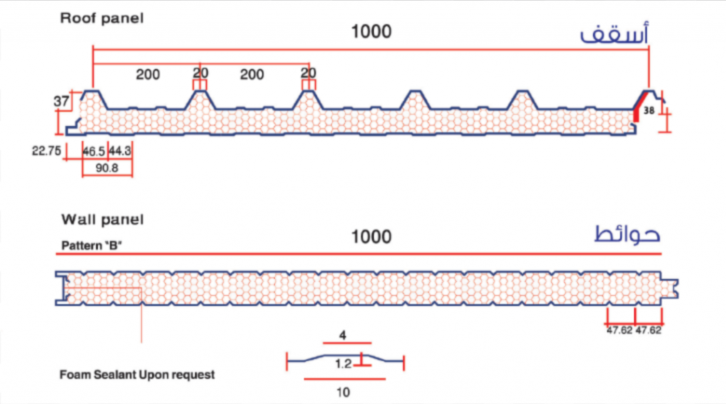

Xinnuo offers you an advanced Sandwich Panel Production Line designed for the efficient production of both roof panels and wall panels—not simultaneously, but with the ability to switch between the two types. This flexible production line significantly reduces equipment footprint compared to purchasing two separate lines, making it a cost-effective solution for your production needs.

We primarily offer PU core sandwich panel production lines and Rock Wool core + PU core lock-edge sandwich panel production lines. The key feature of our offering is the Z-lock joining method, which ensures strong and reliable connections for your panels.

With Xinnuo's Sandwich Panel Production Line, your products will be hot sold. As the PU sandwich panel with a pear of Z-lock edges are welcomed nowadays.

However, we also offer customization options to meet specific customer needs. If required, the line can be adjusted to produce panels using alternative core materials such as Glass Wool or EPS, and can be configured with a standard lap joint instead of the Z-lock.

This versatile production line combines efficiency, flexibility, and cost-effectiveness, making it the ideal choice for businesses seeking high-quality sandwich panels in a streamlined, space-saving production process.

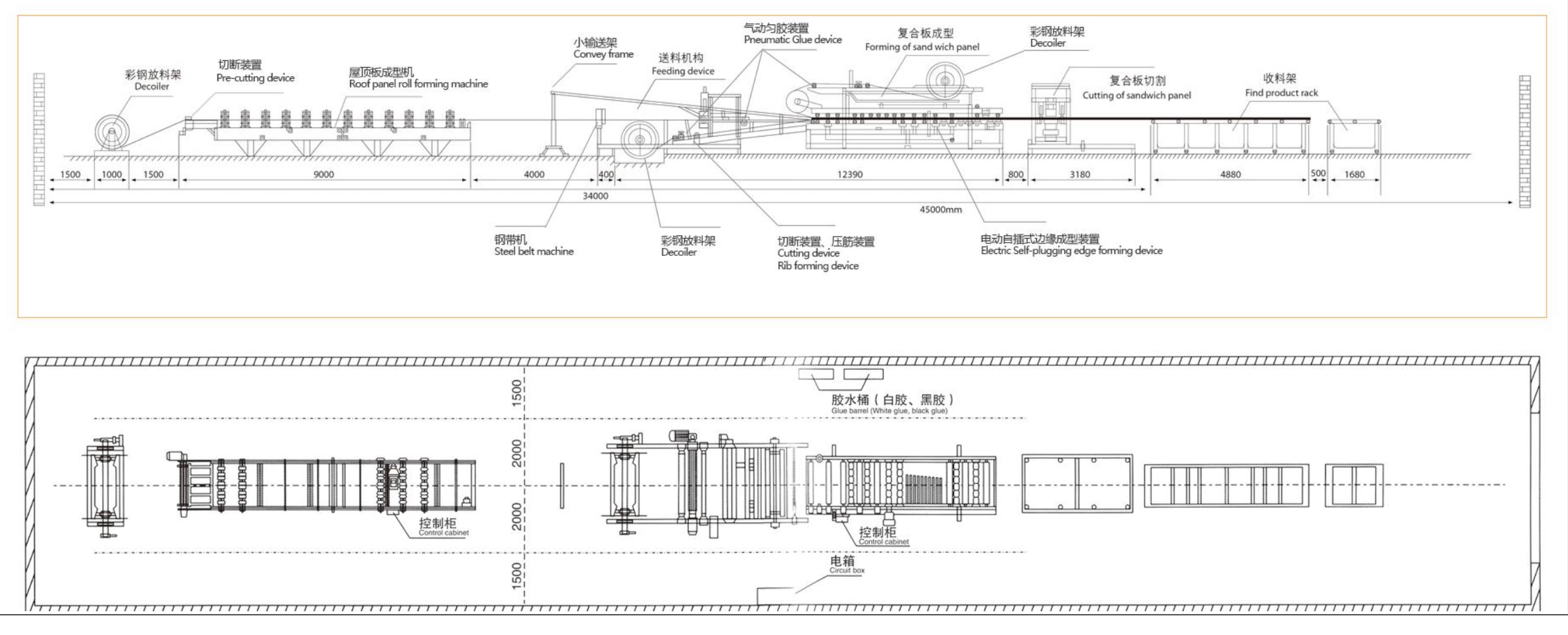

The Sandwich Panel Production Line is a complete, high-efficiency manufacturing solution designed to help businesses start producing sandwich panels from scratch. This fully integrated system includes all the necessary machines, tools, and accessories required for panel production, reducing the need for separate purchases and optimizing sea freight costs.

CAN U IMAGINE a PRODUCTION LINE filled with LEADING TECH?

HERE it is, in XINNUO!

One of the major advantages of our production line is its advanced automation technology. Equipped with internationally leading machinery, the system operates with a high degree of automation, ensuring precise manufacturing and minimizing manual labor. This results in higher production efficiency, improved product consistency, and reduced operational costs.

Different core materials? No problem!

Our Sandwich Panel Production Line is highly versatile and supports the manufacturing of panels with different core materials, including PU (Polyurethane), Rock Wool, EPS (Expanded Polystyrene), and XPS (Extruded Polystyrene). Since different core materials require specific production processes, we offer customized production line configurations tailored to each material type. This ensures that our customers receive an optimized solution that meets their exact production needs.

Your products will be HOT & POPULAR

The finished sandwich panels produced by our line are widely used in the construction industry for applications such as roofing, wall cladding, cold storage rooms, and prefabricated buildings. These panels provide excellent thermal insulation, fire resistance, and durability, making them a preferred choice for energy-efficient and high-performance building solutions.

With our fully integrated system, advanced automation, and customized configurations, our Sandwich Panel Production Line is the ideal solution for businesses looking to establish or expand their panel manufacturing operations. By investing in our production line, manufacturers can achieve high efficiency, superior product quality, and reduced operational costs, ensuring a competitive edge in the market.